Since last time I wrote, I’ve made a few more pieces. Note: pieces are not in chronological order. A few technical details are at the end.

We’ll start with a recent one that I’m proud of:

Yep, it’s a vase with rats coming out of it. The black glaze is Marilee’s Lava with 7% Mason 6666 black stain, which I put together myself. I have now manufactured a few glazes, including this; a lichen glaze which slid so dramatically that I haven’t dared to use it on a real piece; and a supposedly mint green which actually came out so much more matte than the reference photo that I suspect I must have fucked up somehow. I’ve also played with oxides some and gotten results varying from unnoticeable to garish to awesome. I’m not sure how I feel about a process with such high-variance results but I’ll probably keep exploring anyway.

Here’s the first piece I made that I still like:

Probably I’ll stop liking it once I improve further. I enjoy the texture, but I wish it were more precise. I still don’t really know how to get precise lines – somehow, even with a ruler, it always comes out messy. So I’ve been trying to learn to make pieces that embrace the mess.

I also made vases as holiday presents for everyone on my team. The project we were working on is called The Aleph (after the Borges story), so all of the vases have Alephs on them. This is my favorite:

One co-worker in particular got excited about the pottery, so I made her a casserole:

My cats insist on photobombing my pottery photos. This is the rare Mutex photobomb – it’s usually Semaphore. The texture on the casserole was made with an old daisy wheel. The piece is really quite large – it cooks^Hholds almost 16 lbs of cat. I used S762 kitchenware clay, a buff stoneware with fine grog. It reportedly goes happily into a cold oven without cracking, so I guess the body lives up to its name. Unfortunately, most of the studio’s glazes, and some commercial glazes come out muddy or crazed on this body, so I’m pretty limited in where I’m willing to use it.

One piece I made out of it was my second orcish teapot. But before I get to the second one, I have to show you the first:

The body here has exactly the hue I wanted, but about two shades too light. That’s significantly better than some other possible outcomes: the glaze combination I used is a bright green celadon on top of a chameleonic red-brown. Too little green, and you get mud; too much and you get blobs of snot.

Other folks insist on calling this a warthog teapot, but what does a warthog need with a teapot? Maybe the orcs used warthog tusks to make it. Another potter at my studio had been doing a bunch of stuff with spikes, and I was a bit inspired. Peter’s spikes are broader than mine, and straight rather than bent. He throws them on the wheel, which I did for these and for my doorknob, but which I’ve since given up: handbuilding them is faster for me. And it’s easier to get close-to-identical copies, at least at my skill level.

I like the idea of a second draft of a piece, and wish I had the patience to do it more often. The casserole above is actually a second draft: the first one was too thin and ended up cracking. The second one has straighter walls and better texture, and I think the handles are nicer too.

Here’s that second orcish teapot:

.

.

The second orcish teapot did not come out the way I had planned, but I am not disappointed, because it’s pretty metal. Literally: the black glaze is primarily black copper oxide, and the horns have some red iron oxide stirred into the clear. Copper oxide usually produces green, and I had hoped to reproduce something like the original glaze by adding a bit of copper oxide to a not-green-enough glaze. You can see the normal copper green where the oxide has bled into the white interior glaze. That’s not the color I wanted on the outside either, but it’s attractive if not particularly orcish.

Britt suggests adding bentonite to oxides to get a more even application. Brickhouse’s studio oxide washes don’t have this, so they settle out very rapidly, making it hard to get an even application. I made up a copper oxide wash with some methylcellulose (AKA “CMC gum"), which I have used in the kitchen in the past. It burns off in the kiln, but suspends the oxide enough to get an evener application. However, I think I might have more oxide in this wash than I really want. Copper oxide is quite corrosive: one little drop of the oxide glaze slid off my piece and ruined a kiln shelf.

I know that the standard approach here is to glaze a bunch of test tiles, and not glaze the final piece until the test tiles are done, but the turnaround time on test tiles can be up to three weeks, so I often test on finished pieces. I do take glaze notes inside a crappy webapp I threw together, which at least helps me avoid making the same mistake twice.

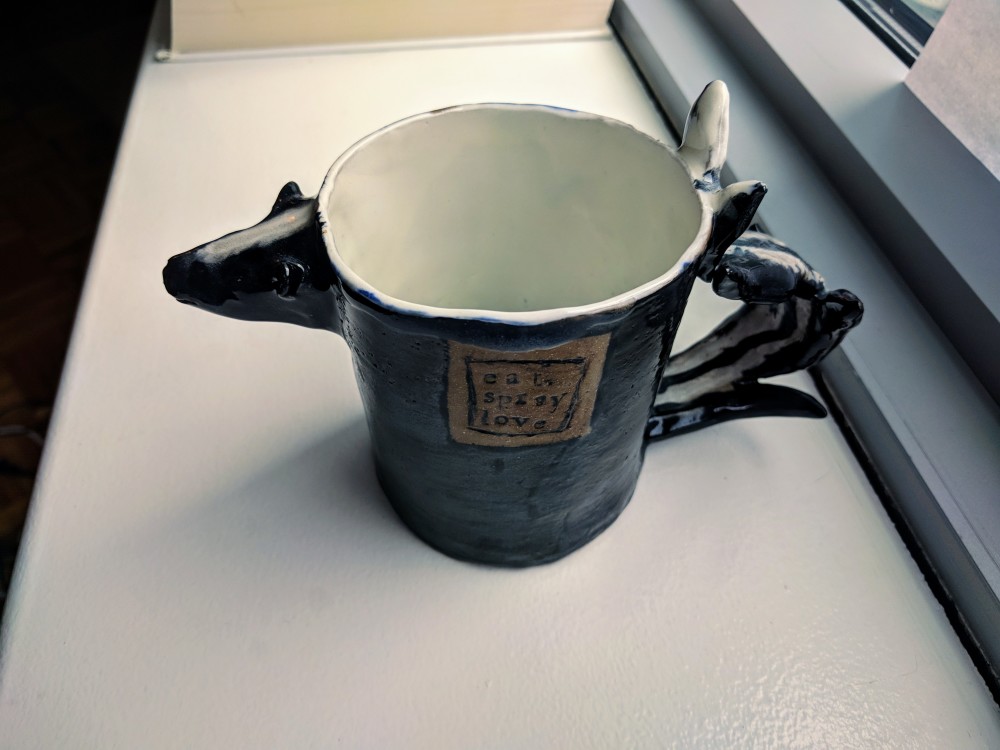

All of these horns got me excited about animal forms, so I went back to handbuilding. The rat vase was the first thing I made with animal faces. Then I made a skunk mug:

I have to admit that this one, too, was partially inspired by [Peter]((https://www.instagram.com/potteraguero/)’s work – he had been doing “eat, fart, love” mugs ("I don’t pray”, he explains). So when I made a skunk mug, the “eat, spray, love” slogan came to me in a flash. The face has kind of a funny shape, but I think it’s not too far from what a real skunk’s face looks like. It’s just that our mental image of a skunk has been warped by Pepé Le Pew.

Another thing that inspired me to make animal forms was this Pikamug:

Once I had made this for one cousin, I knew I would have to make something for his sister, and their mom suggested Ponyta:

One rule I have is that everything I make has to be at least somewhat functional. This constraint is somewhat arbitrary – just about anything hollow could be a vase. But it does mean that I am forced to pay attention to how a piece could be used, and think about smoothness and weight. I should probably institute a “no vases” rule at some point, since I basically never use a vase for anything. Maybe I’ll ban teapots too, except that I have yet to make a teapot that’s technically even base-level competent yet. For instance, the first orcish teapot doesn’t pour very well because the glaze covered up the holes. The second’s spout is too low. So I may have to make a few more of those.

Here’s a completely boring bowl where I like the glaze; it reminds me of a night sky:

The waiting is a real struggle: the most recent work I can show is some jars that I threw in late December, and then sculpted the lids of in January, and then glazed a few weeks ago, and just got out of the kiln. In fact, the third pot’s lid didn’t look great after glaze firing, so I’ve reglazed it and am refiring it. Here are the remaining two jars: a French bulldog, and a demon:

This delay means I can’t show you my alligator teapot or my Baba Yaga’s hut teapot, or my seed pod vase, or my second doorknob, which is completely different than the first one. So I guess I’ll have to post again.

Technical details:

I’m working at Brickhouse Ceramic Arts Center in Long Island City. My primary clay body is the studio’s brown stoneware, but I’ve also used Laguna B-Mix and S762 from Ceramics Supply. The studio fires at Cone 6 in oxidation. I use the studio’s glazes, as well as some commercial glazes from Amaco, Mayco, Coyote, and Potter’s Choice. If you like any of the glazes above and want more details, let me know and I’ll happily share.

Next post: A problem I don't know how to solve

Previous post: Variance and dynamic range in Lost Cities and Keltis