A friend of mine ran this event called GlowCamp, which was an unconference about lighting design. Since I know nothing about lighting design, I decided to attend. But since unconferences are all about participation, I knew I had to bring something. So, with a deadline and a theme, I set to work.

Count to Nine is a puzzle. Pull the chains in the correct sequence, and the lights go on, one-by-one. Pull the wrong chain, and everything turns off. There's a logic to the pulls, but you'll have to figure out what that logic is.

I should start by saying that I have only the tiniest idea of what I'm doing with most physical materials. I've spent too much of my time in the infinitely malleable world of computer code. So I'm not even sure what's interesting and what's perfectly standard.

I started with a sheet of copper. I really like the organic shapes you can get by just hammering with a ball peen. I started out by laying the copper on a stack of towels. This supports most of the sheet, but compresses well under the hammer's head. I've never seen towels used this way anywhere, although I'm sure I'm not the first to discover it. It took about a dozen rounds of hammering and annealing to get the shape right.

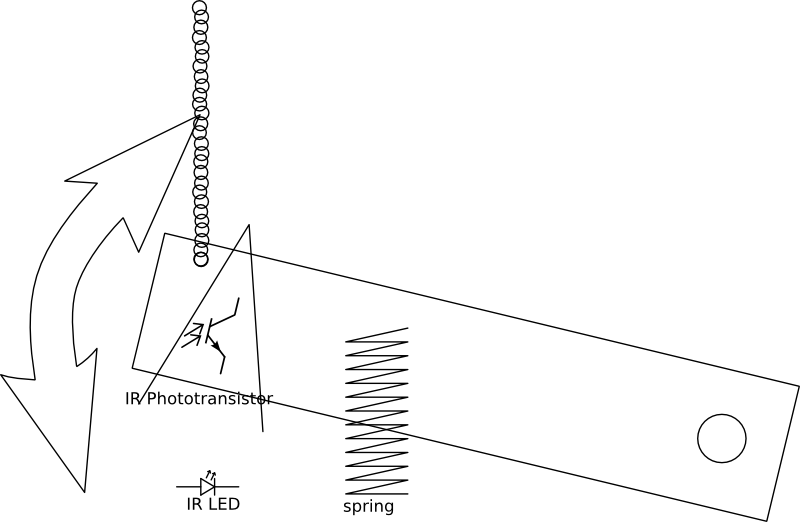

Once I had the basic form, I cut a piece of wood to put the mechanicals on. I hooked arms to springs, and the pull chains pull on the arms. It was important to me that the chains have a smooth, clean pull and gentle spring back. Otherwise, I would probably have just used strain gauges. The pull is sensed with infrared, because I had initially planned to have analog pulls, and thought this would give me an easy way to do this. Actually, it was a bit finicky and stupid.

A friend of mine who actually works with metal professionally suggested tube rivets for grommets for the holes. I happened to have some 1/4" aluminum tubes around, which I cut and hammered between a dapping punch and a ball peen. I used a similar technique to create holders for the LEDs, but I only expanded one end of the tubes. I used many layers of fancy paper to give the lights a nice diffuse glow. Epoxy held them in place, and Sugru between the lights kept the bleed-though down.

The programming only took about 10% of the time. As usual, a tiny bit of user testing discovered many bugs and oddnesses. I was extremely pleased when someone finally solved it for the first time.

Completed August, 2010